By Michael Lauzon

CORRESPONDENT

Published: April 29, 2014 4:27 pm ET

Updated: April 29, 2014 4:28 pm ET

Image By: Lux Research Inc.

Lux Research expects sales for 3-D printing will only grow.

Greater freedom in plastic material choices will help fuel growth in 3-D printing markets, according to the lead author of a new Lux Research Inc. report.

Anthony Vicari said in a phone interview that use of plastics in 3-D printing has been confined mainly to making prototypes since properties of 3-D printed plastic parts typically fall short of what a manufacturer wants for production.

“For commercial printers, a customer is almost locked in for material choices,” Vicari explained.

The 3-D printing heads usually are configured to run a limited slate of polymers which are supplied by the printer manufacturer. The Lux study estimates 3-D printer suppliers mark up the price of their materials by as much as 10 to 100 times.

“This approach was tolerable when companies only used 3-D printers for prototyping, but it remains a major impediment to the use of 3-D printing for production parts,” Lux stated in a news release.

Arburg GmbH & Co. KG’s entry into 3-D printing, the Freeformer — introduced at the K trade show in Düsseldorf, Germany in October — promises to allow additive manufacturing using standard resins, rather than those linked to a specific 3-D printer maker.

Vicari expects as the industry evolves, commercial 3-D printer users should be able to access more plastics, opening more markets for 3-D printed industrial parts. The trend to wider material choices is already underway in consumer-oriented 3-D printing, he added. Hybrid printers are emerging that can print a range of materials.

Plastic material restrictions in commercial 3-D printing have created tension between printer suppliers and manufacturers who want to adopt the technologies for volume production.

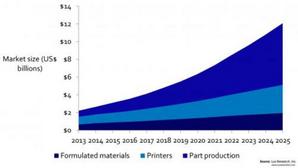

Boston-based Lux predicts the total market for 3-D printers, printable materials and printed parts will nearly quadruple to $12 billion in 2025. Plastics-based technologies currently are dominant, accounted for about 90-95 percent of the 2014 market value of nearly $3 billion. Industrial applications, now accounting for nearly 90 percent of the market, will continue to be dominant, but consumer uses will grow.

Vicari said one major limitation of plastic-based 3-D printing is the weak bond between printed layers. Suppliers are trying to address this through the use of reinforcements, adhesive layers and surface treatments.

Metal-based 3-D printing, by contrast, when combined with heat treating, can achieve part properties close to those obtained by metal machining. Metal-based 3-D printing is proving especially valuable in aerospace applications where high-value alloys are converted to parts with far less wastage than in machining metal blanks.

Expiring patents will help trigger 3-D printing growth, Lux predicted. They should open the field to less costly systems and greater capabilities. Consolidation is rampant in the industry as new players pop up, and as established suppliers expand sales and capabilities.

3D Systems Corp., for example, has acquired some 50 companies and the acquisitions have accounted for more than half its growth, Vicari estimated.

“How 3-D Printing Adds Up: Emerging Materials, Processes, Applications and Business Models” forecasts the market will grow in sectors as diverse as aerospace, medical, automotive, consumer products, architecture and electronics. Parts production will be the fastest growing segment, reaching about $7 billion in value by 2025. Formulated material sales will grow to $2 billion while the value of printers sold will reach $3.2 billion. |