By Nina Ying Sun

ASSISTANT MANAGING EDITOR

Published: May 9, 2014 12:04 pm ET

Updated: May 9, 2014 12:14 pm ET

Image By: Rich Williams

Ten years ago in Shanghai, Plastics Newscovered the Chinaplas show for the first time. Back then, Milacron had just manufactured its first injection press in China, GE Plastics was still GE Plastics, a dollar exchanged for 8 yuan RMB and Shanghai’s sky was still blue.

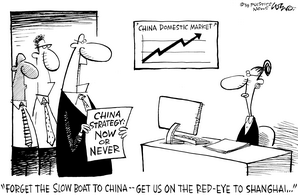

After a busy decade filled with growth numbers, investments and expansions, this year’s Chinaplas left me with a different takeaway message. Call it a milestone, a turning point, or a new era — China’s domestic market and domestic customers should be the core of your latest China strategy.

Yes, low-cost manufacturing and exports are a passing trend. Chinese domestic consumers and brand owners hold the key to the future.

For many leading materials and machinery suppliers — DuPont, Brückner, Engel, just to name a few — Asia, particularly China, either has become or is becoming their largest market. Even more impressive than the market volume is the growth. Love it or hate it, China remains the growth engine for our global industry.

China’s nearly 14,000 plastics processors saw their total sales climb 15 percent in 2013, with profit up by 17 percent. The growth almost exclusively came from China’s domestic market, as exports stayed flat with a mere 1 percent year-on-year increase.

The faster-than-GDP-growth rate continued in the first quarter of 2014. China’s rubber and plastics processing sector reported an 11 percent sales increase and a 16 percent profit hike.

Beyond these cold, hard numbers, we can also get a taste of China’s changing role from the warm and fuzzy rhetoric we heard at Chinaplas. Clariant believes: “Our future lies in Asia.” Davis-Standard stated: “We’ve made China our home.” Similarly, Engel said: “Asia is not just a market for us, it’s a home base.”

There used to be a time when Western suppliers simply followed their multinational customers to China. But Chinese domestic customers — brand owners and converters — have grown to be the main revenue source for just about everyone I’ve spoken to. The percentage varies, from 70 percent for Demag, to 70-plus percent for Dow Packaging, to 80 percent for Arburg.

That’s exactly why it’s crucial to build up production and research capacity in China to serve the local customers with the shortest response time possible. The Chinese market, not as mature and established as the developed world, is dynamic and fast-moving. Combined with the enormous size, it requires manufacturers to be able to swiftly change design and production on a large scale.

Multinational suppliers have really stepped up their effort to help Chinese customers identify trends, develop applications and improve productivity. With an increasing number of R&D centers launched and expanded in China over the past few years, the latest emphasis seems to be on global collaboration.

It’s not a business cliché. Global players are indeed leveraging their resources worldwide to stay ahead of the game in this fiercely competitive market. The Pack Studio Dow launched in Shanghai last week is a timely example, offering R&D but also marketing and design expertise. Here, Dow Packaging works directly with brand owners on innovative solutions that cater to Chinese consumers’ particular needs.

With massive urbanization continuing to take place and millions of middleclass consumers changing their lifestyle, China is at the last stage of its economic boom, before eventually slowing down into a more mild growth model.

It’s go big or go home. It’s now or never. |