David Vink

EUROPEAN PLASTICS NEWS

Published: October 24, 2013 1:25 pm ET

Updated: October 24, 2013 1:32 pm ET

Image By: Caroline Seidel, Plastics News

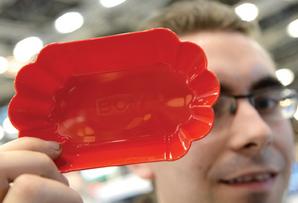

A Dr. Boy staff member holds up a plastic bowl produced Oct. 18 at K 2013.

DÜSSELDORF, GERMANY — Dr. Boy GmbH & Co. KG (Hall 13/A43) is well known as a firm opponent to all-electric drive injection presses. Energy savings are nevertheless a major theme for the company at K 2013, with presentation of an EconPlast plasticizing system with 50 percent less energy consumption, for which Boy has taken out a patent.

Boy gave an example of a plasticizing unit processing at a rate of 6.48 kilograms per hour that enables power consumption with EconPlast to be cut to 1.5 kilowatts, from 3.1 kilowatts for a machine without EconPlast.

In general, Boy talks about EconPlast requiring up to 40 percent for heating power; around 60 percent less energy loss during dosing; faster and more direct temperature control with associated shorter starting and heating times; and improved feeding zone cooling with "clearly lower energy loss."

Rejects are also lower, according to Boy, because of low-friction material treatment by the screw, and there is optimized melt homogeneity.

Marko Koorneff, vice president of sales and service at Boy Machines Inc. in the United States, said the energy savings is so significant that Boy machines equipped with EconPlast "achieve the same savings as all-electric machines. Using an electric drive on the plasticizing unit was the obvious thing to do."

The EconPlast system has a grooved barrel with electrical resistance heaters inside.

"This means a better contact area for heat transmission, as the heat transfer takes place directly from metal to metal and not as convection from steel through air to steel. And you can still add insulation blankets as well, although they are, strictly speaking, not really required," Koorneff said.

He said that existing Boy machines cannot be retrofitted with the EconPlast system. A special EconPlast website contains a program that enables processors to calculate energy savings.

There has been a marked change in the way that Boy does business, Koorneff said, "as Boy has been previously primarily offering machines off-the-shelf and letting customers manage with them. It is today no longer a matter of the company saying to a customer, 'Here's your Boy 15S, good luck with it.' We are trying to get away from that. Now we want to be an A-Z supplier, working as a partner with customers, finding solutions and providing consultancy services."

Boy has hired staff to support the new approach, Koorneff said, providing an enhanced technical sales interface with customers.

"We have not gone as far as custom-building machines, however. It is more a question of modifying and adjusting them," Koorneff said. "I've been doing this for the past three years, ever since I joined the company [from the extrusion machinery sector]."

Koorneff said Boy's managing partner, Alfred Schiffer, was reluctant about the idea at first.

But because the concept was successful not only in the U.S., but also in the U.K. and Italy, "Boy has seen the results, merits and importance of the new approach," he said.

Koorneff said there is an entirely new image and spirit at Boy, as the company adapts to the changing times. For instance, signage displayed across Boys' stand promotes the company's smartphone apps. The slogan reads: Injectioneering.

The apps were launched in September and include features such as cooling time and clamping force calculations. There are also comprehensive data sheets available via the apps on processing, pre-drying needs and density of many common plastics.

Even the latest Boy control systems screens have been redesigned into a more modern shape, looking not too dissimilar from a smartphone app symbol.

Koorneff said Boy is focused on markets such as medical components, small automotive and aerospace applications. Many of these require high-precision molding. Koorneff said there is a common misconception that high precision and repeatability can only be achieved with all-electric drive machines.

"The density of plastic varies from shot to shot, so the molding machine has to be adjusted to allow for this," he said. "The best way is with a hydraulic machine. An all-electric drive machine can do this by changing the pressure, but all this is just mimicking what a hydraulic machine does, and it is very expensive to mimic."

Koorneff also pointed out that even electric-drive machines need hydraulics for core-pulling applications.

Although Koorneff said Boy uses servo-electric drives for screw and barrel movement in some cases, some of the Boy machines are equipped with double hydraulic pumps.

The pumps enable multiple main and secondary movements to run in parallel and thereby increases machine speed.

"But, in general, there are not many applications for which Boy machines are used where high speed is important," Koorneff said.

Boy has rationalized its machine clamping forces. The 22-ton machines are being replaced by 25-ton models and 55- and 90-ton machines by 60- and 80-ton models. So the range starts with the smaller 25- and 35-ton XS models and extends through 50, 60 and 80 tons to 100 tons.

Koorneff said the 25E has the same footprint and hydraulic system as the 22E it replaces.

Koorneff said there are no plans at Boy to go beyond 100.

At K 2013, Boy has machines equipped with advanced robotic systems, which the company now offers as part of complete production cell systems.

Automation from Awetis Engineering and Manufacturing GmbH is being used on a Boy EVV vertical machine, producing EPDM shaft sealing rings.

Another automated demonstration is making polycarbonate beer glasses of 67-gram shot weight with a 42-second cycle time. For the application, a Boy 60E was fitted with a size 205 injection unit and an EconPlast plasticizing system.

The part is laser printed afterwards, which involves part removal with equipment from AGS Automation Greifersysteme Schwope GmbH (Hall 10/C28). Ancillary equipped for the process was supplied by Bierthe GmbH, laser printing equipment from Bluhm Systeme GmbH (Hall 4/E47), mold temperature control from Hahn Enersave GmbH (Hall 11/G63), clamps from Lenzkes Spanntechnik GmbH (Hall 2/A20) and the conveyor system from MTF Technik Hardy Schürfeld GmbH & Co. KG (Hall 10/H58).

With Boy's new philosophy, such complete systems can be provided as complete packages — maybe not with the beer, however.

Two-component molding is represented by a complex white nylon 6 component overmolded with black thermoplastic elastomer on a Boy 2C Xs machine. The injection unit for the TPE component can be easily removed so the machine can make single-component parts. |